A thousand-year-old material, raw earth construction is making a comeback in modern construction. Embellished with current techniques and technologies, this ancient natural material becomes a true contemporary support for construction.

Do you know how many tonnes of earth will be extracted during the construction of the Grand Paris Express between now and 2023? About 400 million tons according to the Regional plan for the prevention and management of waste from construction sites and public works (Predec). Did you know that we can recover this land in order to use it for construction? This is the purpose of the Cycle Terre project (https://www.cycle-terre.eu/), which perfectly represents the return to center stage of this ancient material. Methods Studio Architecteur provides you with an update on raw earth and straw construction.

1. Raw earth construction

- What is raw earth in construction?

These are very old materials, found everywhere in the world since man began to build your home. The earth is clay concrete. It is a composite building material made from aggregates (pebbles, sands, silts) agglomerated by a binder: clay. You can sometimes add vegetable fibers such as straw, in order to optimize technical properties.

This raw earth can be shaped in the form of bricks or even as mortar, in formwork or as coating.

- Raw earth construction: a sustainable material with low carbon impact

After the Second World War, concrete, steel and terracotta bricks replaced local materials such as wood, stone and earth. Indeed, building in concrete, steel or brick then represented a significant savings in construction time, as well as a significant increase in industrial profits.

Long abandoned, the earthen has always been an interesting material for the protection of the environment due to its low carbon impact. Raw earth ticks the construction criteria in the circular economy.

As a dense material, it has very good thermal inertia qualities, by storing the sun's heat and releasing it slowly in winter, and keeping out the heat in summer.

The proper regulation of hygrometry of an earthen building brings comfort to the occupants, thanks to the perspirability of the walls (i.e. their ability to capture and then release water vapour). Finally, its density makes it a good sound insulator.

Contrary to popular belief, it is a strong material, which resists well to time and bad weather, if we respect the adage "Good boots and good hats".

2. Raw earth and straw construction techniques

- What about its implementation?

Rule number one for a raw earth construction: analyze the earth before using it. Is it possible to use the earth present on the ground for the construction? Using this soil already present on a construction site is very interesting.

For each construction technique (adobe, brick, cob, cob, adobe, etc.) and for each type of coating, it will be necessary to adapt the dosage of the constituents (clay, sand, vegetable fibres, gravel, etc.) in order to obtain the desired qualities.

The two techniques are :

- rammed earth : an adobe wall is made by packing between formwork forming a formwork mix of earth, sand and possibly gravel. The mud wall rammed earth must, like any mud wall, be mounted on a sufficient base to avoid splashing and rising water by capillarity, and a cover.

- mud bricks : In the past, mud bricks were molded by hand and then dried in the sun. Today, manufacturing is done via manual or mechanical presses. A common use today is the creation of internal shear walls, against which a stove is installed.

3. Raw earth in modern construction

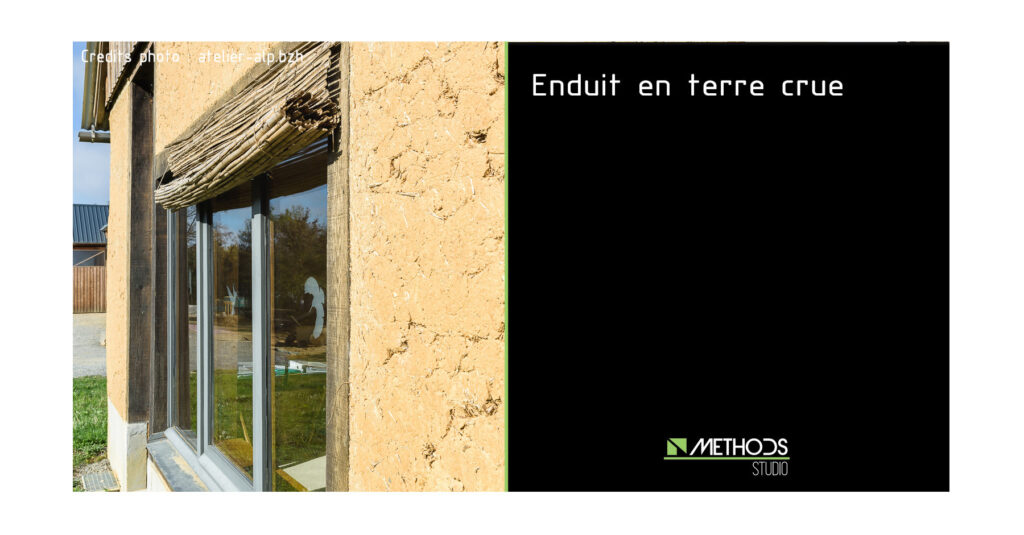

- Raw earth as wall coating

Sign of his return to the front of the stage as modern material, we see the appearance among manufacturers of raw earth wall plasters, ready to use, easily usable by craftsmen.

His matte finish and his natural touch make it a very pleasant coating for the interior of living rooms. Permeable to water vapour, anti mold, it regulates temperature and humidity for optimal comfort. It also adds a layer acoustic insulation.

Can also be used outdoors, however it will have to be protected from the rain with a large overflow.

- Raw earth and 3D printing

Did you know that it is possible to build a whole house in raw earth thanks to a 3D printer ? Such printers, dedicated solely to earth construction, make it possible to quickly build dwellings with local earth. This type of construction is already cost competitive, because even if the printer itself represents a significant cost of installation, we realize great savings on the rest. No transport, no other materials, no scaffolding and other tools needed for construction. Construction by 3D printer makes it possible to break free from the usual construction codes, dictated by the constraints of the materials used. The only form limit is that which can be endured by the earth!

Raw earth construction can be an option to consider for your future home, especially to build in an eco-construction logic. You will, however, need to ensure that the local soil is suitable for the construction you wish to achieve. Ecological, insulating, healthy and durable, raw earth has many advantages. But if 30% of the inhabitants of the planet are sheltered in raw earth constructions, this technique is almost no longer used here.

Construction, like all other sectors, must take an ecological and sustainable turn.

New techniques are bringing raw earth back to center stage, whether through ready-to-lay coatings or the use of 3D printing technology. The dissemination of these new techniques will make this material known, perhaps to facilitate access to earthen construction for a greater number.

So raw earth, past and future of construction?

For further :

- Our partner Architect specialist in Raw Earth: Atelier ALP

https://www.atelier-alp.bzh - The Cycle Terre project for the reuse of Greater Paris waste

https://www.cycle-terre.eu/ - How is raw earth made?

https://www.atelier-alp.bzh/actualites/terre-argile-lian/ - The thermal inertia qualities of raw earth

https://www.atelier-alp.bzh/actualites/linertie-de-murs-en-terre-crue/ - Detail of 4 raw earth construction techniques: https://www.batirama.com/article/169-terre-crue-4-techniques-a-redecouvrir.html

- Testimony of a resident of a straw earth house:

https://www.youtube.com/watch?v=YWdmnAQPIeY - Ecological raw earth plaster

https://www.youtube.com/watch?v=vIc9f-zUO6s - Technical prescription for the construction of a rammed earth wall

http://www.construction-pise.fr/IMG/pdf/aqc-n143article-la-pathologie_humide-du-pise.pdf